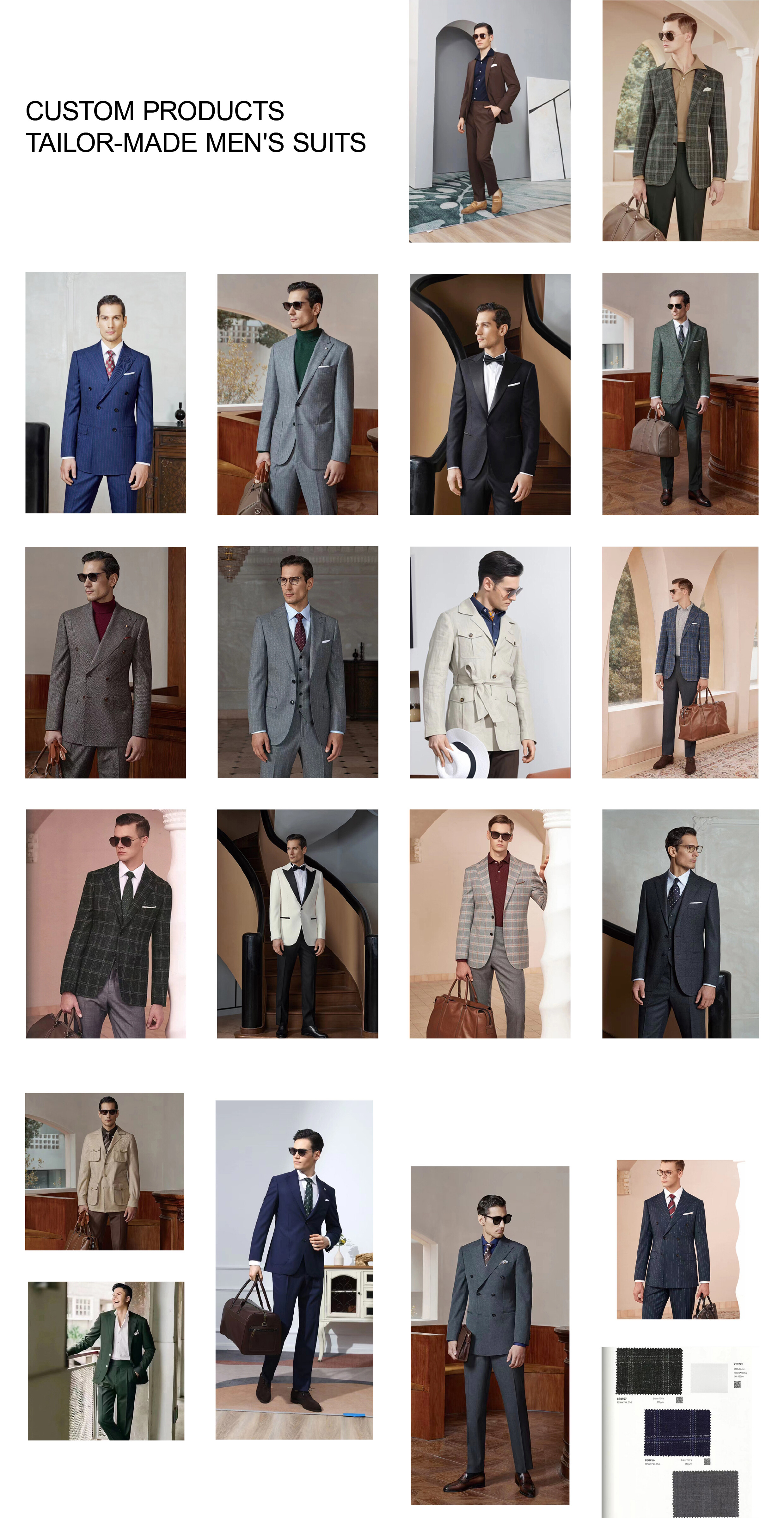

Premium Quality | wholesale price

Why wait? Get Your Free Quote Now!

Product Introduction

The manufacturing process of suits: full linen lining, half linen lining, and bonded lining.

What is linen lining? In the process of making a suit, in order to keep the entire front piece, especially the front chest area, straight, something needs to be sewn or filled between the fabric and the lining. Among the materials available for this layer of stuff in the middle, the most suitable is the lining made of wool, cotton and linen, so what we call full linen lining and half linen lining refer to this layer of filling. Since the use of more or less linen lining, or its presence or absence, can greatly affect the overall craftsmanship level of a suit jacket, and there is also a significant difference in cost, it has gradually evolved into full linen lining, half linen lining, and bonded lining to refer to the three levels of suit craftsmanship, and also represent the three grades of high, medium and low. Let's explain the three processes below.

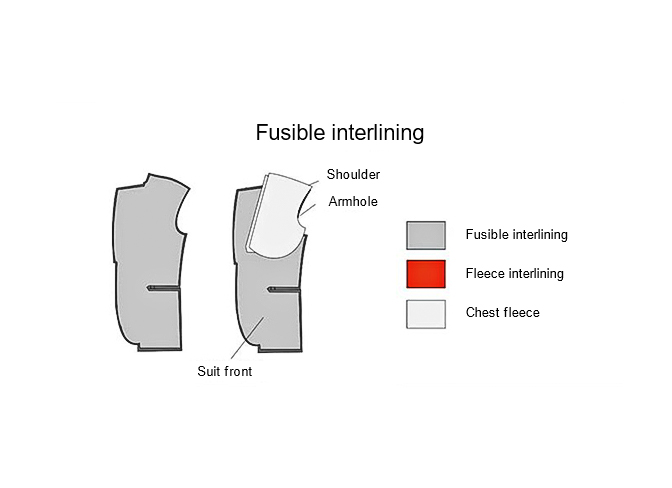

Fusible interlining

In terms of the method, the fusible interlining is to directly glue the woven interlining to the inside of the fabric through viscose, and then add the chest velvet inside, and then sew the fabric and lining together to make the garment. In this way, there are fewer processes and it is more convenient to sew. The front chest is more stylish than the jacket without fusible interlining, but it is relatively dry and not wide enough. The addition of fusible interlining will make the breathability worse and the comfort will also decrease.

The method of fusible interlining is suitable for some harder fabrics to make the front piece look more stiff, which just caters to the characteristics of chemical fiber fabrics. However, the high content of chemical fiber in the fabric affects the adhesion of the fusible interlining, which is easy to bubble when exposed to water, and is easy to deform after wearing for a period of time, and it cannot be restored after deformation, so the service life is relatively low.

There is also a kind of fusible interlining suit that also adds a layer of linen interlining on the front chest, but the linen interlining only goes to the bottom of the lapel, and the lapel is still fusible interlining. Without linen interlining, the effect of wearing is slightly better, which is considered a high-end fusible interlining.

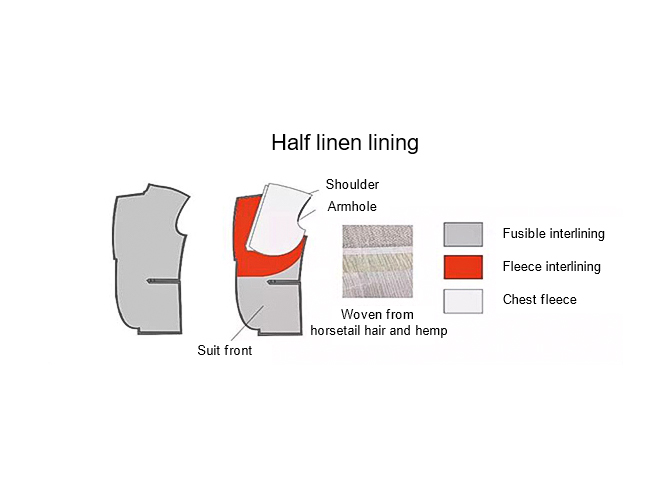

Half linen lining

Half-linen interlining refers to the interlining that is half filled between the outer fabric and the lining. It is only present above the waist, but not below the waist. Half-linen interlining can be regarded as an evolution of bonded interlining. The addition of linen interlining makes the front chest area more rigid, full and elastic, and the curvature of the lapel is natural, stable and not easy to deform, and the service life is increased. However, since there is no linen interlining in the lower part, some practices have to follow the process of bonded interlining, such as bonding interlining. Most people think that since the linen interlining has been filled, there will be no need to bond interlining, but that is the practice of full linen interlining. If half-linen interlining is not bonded, there will be only two layers of cloth below the waist, which is in sharp contrast with the upper part and the hem is too light and informal. In order to keep the overall coordination of the front piece as much as possible visually, bonding interlining is an indispensable link, and it needs to be bonded from the top to the bottom.

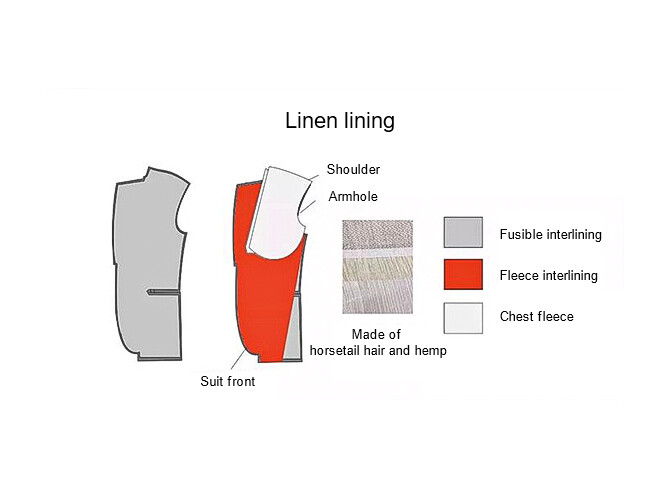

Linen lining

The biggest difference between full hemp lining and the above two processes is non-stick lining, because the hemp lining from top to bottom can completely replace the woven lining, and all the advantages, disadvantages and production difficulties of full hemp lining are extended from this.

Main advantages of full hemp lining:

1. Completely restore the characteristics of the fabric.

Whether it is the breathability level, drape, feel, or even glossiness, the better the fabric, the better the final effect of the clothes. The fabric is poor, and the final effect of the clothes will also decrease. Therefore, the full hemp lining process is often accompanied by high-end fabrics.

2. The weight of the clothes is significantly reduced, and it is more comfortable to wear.

The part of the front piece close to the shoulder will minimize the sense of oppression after the upper body.

3. Long service life.

The storage time of the suit is the same as the storage time of the fabric. Because the semi-hemp lining and the bonded lining are bonded, the glue on the woven lining will slowly fail over time, and eventually fall off and the clothes can no longer be worn. It should not be a problem to keep a good semi-hemp lining for five years, but it is also easy to keep the full hemp lining for more than ten years.

The difference between the three processes

How to distinguish the three processes

Because the connection methods of the linings and fabrics of different processes on the chest and hem are different, you can simply identify which process is used by judging the number of layers on the chest and hem. The linings of semi-linen lining and full linen lining are only stitched together at the lapel with thread, while the adhesive lining is glued together.

3 layers on the chest and 3 layers on the hem, that is, full linen lining;

3 layers on the chest and 2 layers on the hem, that is, semi-linen lining;

2 layers on the chest and 2 layers on the hem, that is, adhesive lining;

(PS: Note that these are all in the case of suits with lining)

Factory Showcase

Company Introduction

Shandong Zhongshi International Trade Co., Ltd. integrates clothing design, development, production and sales. It currently has more than 300 employees. We strive to build a clothing cultural and creative center. With the continuous improvement of the company's technical strength and comprehensive strength, in recent years, it has focused on the production and research and development of high-end suits and professional wear, and established a special boutique production workshop. The company's headquarters park covers an area of more than 100 acres, with more than 50 engineering and technical personnel. The main equipment includes computer high-speed sewing machines, various imported suits, and ironing equipment. The company has a world-class French Lectra CAD-assisted design system, an American Gerber automatic cutting system, four fully automatic intelligent hanging clothing production lines, and a high-end suit production workshop, all of which use the German Durkopp production process. The company continues to build its own brand and establish a good brand image. The customer satisfaction, customer loyalty, performance results of products and services, and market share have all steadily increased.

FAQ

Q. What does your company specialize in?

A. We are a clothing manufacturer with our own factory.

We specialize in jeans, suits, jackets, uniforms, T-shirts, etc.

Q. Do you accept OEM orders?

A. Yes! Customers' logos and patterns are acceptable.

Q. Do you support customization?

A. Yes, we have one-to-one clothing customization

Q. What kind of clothing technology do you have?

A. Trust us! We are experienced in 2D/3D embroidery, screen printing, rubber printing, puff printing, etc.

Q. Can you put our brand on your products?

A. Yes. If you can meet our MOQ, we can print your logo on the product and packaging.

Q. How do you ensure the quality of your products?

A. 1) Strict testing during production.

2) Strict sampling inspection before the product leaves the factory to ensure that the product is packed in good condition.

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.